Object Shape Error Response using Bayesian 3D Convolutional Neural Networks for Assembly Systems with Compliant Parts

Authors: Sumit Sinha, Pasquale Franciosa and Dariusz Ceglarek from University of Warwick, U.K.

Abstract:

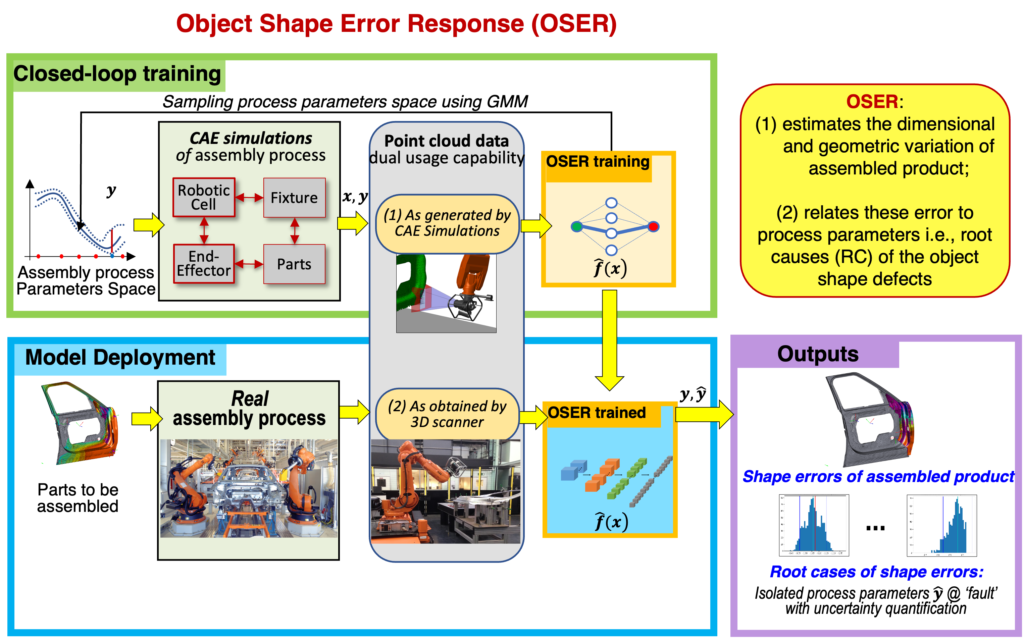

The article contributes to the overall initiative driving zero-defect manufacturing strategy by accelerating the development of in-process quality improvement capabilities, specifically Root Cause Analysis (RCA) of quality (6-sigma) defects in multi-station assembly systems. In recent years, deep learning architectures have matured significantly to provide unprecedented capabilities for RCA of quality defects in complex manufacturing systems which was otherwise infeasible using previous statistical approaches. This article proposes a novel object shape error response (OSER) to estimate the dimensional and geometric variations of assembled products and then, relates these to process parameters, which can be interpreted as root causes (RC) of the object shape defects. The presented OSER deep learning architecture is underpinned by integrating (i) Bayesian deep learning with (ii) 3D Convolutional Neural Networks (CNN); and, (iii) Computer-Aided Engineering (CAE) simulations of assembly systems. Compared with existing methods, the OSER: (1) addresses a novel problem of applying deep learning for object shape error identification instead of object detection; (2) overcomes fundamental performance limitations of current linear approaches for RC analysis (RCA) of assembly systems that cannot be used on point cloud data; and, (3) provides capabilities for unsolved challenges such as ill-conditioning, fault-multiplicity, RC prediction with uncertainty quantification, and learning at design phase when no measurement data are available. Comprehensive benchmarking of the OSER with existing machine learning models demonstrates superior performance with = 0.98 and MAE = 0.05 mm, thus improving RCA capabilities by 29%.

Additional information:

- Open source Implementation of the paper on GitHub – https://github.com/sumitsinha/Deep_Learning_for_Manufacturing

- In-Process Quality Improvement (IPQI) Project Page – https://warwick.ac.uk/fac/sci/wmg/research/materials/dlm/projects/ipqi_new/