A Vision-Based System for Internal Pipeline Inspection

Claudio Piciarelli, Danilo Avola, Daniele Pannone, Gian Luca Foresti

Extended abstract:

The regular internal inspection of waterworks or sewer pipelines is a fundamental maintenance task to guarantee the correct functionality of the infrastructure and to prevent incidents. Even if the pipeline is designed to last for a long period of time, it can be affected by a wide range of problems, such as cracks, collapses, defective junctions, obstructions, etc. Ignoring such defects could lead to system inefficiency, economic losses, environmental issues, or even potential dangers for human beings.

Visual inspection of the internal surface of pipelines is usually done by means of robotic rovers or floating platforms, mounting proper camera sensors and lights. The inspection can be done either on-line or off-line. In the first case, a human operator can see the acquired video as the inspection is being executed, and he can monitor the internal surface by means of a motorized camera head, which can be manually oriented. The advantage of on-line approaches is that defects can be detected in real-time, however it is often unpractical in long pipelines because of the lack of a reliable communication between the sensor and the display base. In the off-line approaches, a video sequence is recorded on-board, and it is later retrieved when the sensor is extracted from the pipe. These approaches are more common for long pipelines, however the camera cannot be oriented toward the relevant areas to be monitored. To overcome this issue, wide-angle sensors (e.g. hemispheric cameras) could be employed, in order to acquire images of the whole internal pipe surface surrounding the camera. However, the final video sequence must still be analyzed off-line by a human operator, which is a long and tedious task.

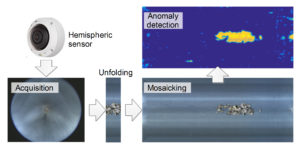

The aim of the proposed work is to define the computer vision and machine learning algorithms that can be employed to ease the task of human operators. The system acquires video sequences with a hemispheric camera, unfolds them to ease the visual inspection, and automatically highlights the zones where a potential defect could be detected. The unfolding procedure combines both geometric properties and image mosaicking techniques specifically tuned for the pipe inspection case in order to create a flat view of the internal surface. However, manual inspection of such images is still a time-consuming process: the major achievement of the proposed work is to drastically reduce inspection time by automatically detecting the areas where a visual anomaly is present, thus requiring the human inspection only on a limited set of image portions. The proposed work identifies anomalies by detecting outliers in LBP visual features. The technique, inspired by one-class Support Vector Machines, is based on a kernel method and automatically identifies the manifold in the kernel feature space where normal data reside. This allows to detect image patches which visually differ from the rest of the pipe surface, and the connected regions of these patches represent the image portions which require manual inspection by a human operator.