Performance Supervised Plant-Wide Process Monitoring in Industry 4.0: A Roadmap

Authors: Yuchen Jiang, Shen Yin, Okyay Kaynak

Extended Abstract:

The intensive research and development (R&D) efforts directed towards large-scale complex industrial systems in the context of Industry 4.0 indicate that safety and reliability issues pose significant challenges. During online operation, system performance degradation will lead, not only to economic losses, but also potential safety hazards. In the existing research and technical routes, the target of the fault diagnosis systems is to trigger alarms to report the fact of the existence of malfunctions as well as the underlying reasons accurately. However, it remains unanswered how urgent it is to fix it, and what degrees of fault-tolerance, maintenance, and fault recovery are needed. Further analyses are necessary to evaluate the impact of the detected fault on the plant-wide performance.

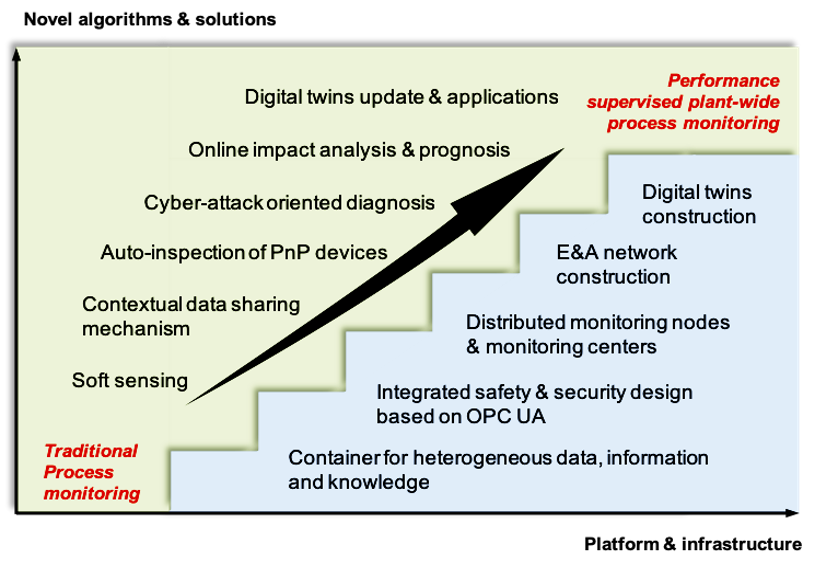

In this article, to enable a more comprehensive and precise description of the plant-wide operational status, the roles of the commonly used performance metrics, the state-of-the-art performance evaluation approaches, as well as the performance-oriented and plant-wide process monitoring techniques are investigated. On this basis, an alternative straightforward technical route, embedded in the cyber-physical-social system framework is proposed.

The paper rethinks the technical route of plant-wide process monitoring and highlights the alternative research route where the construction of performance evaluation systems and the development of performance-oriented fault diagnosis approaches play the central role. With more practical issues in large-scale industries taken into consideration, especially to deal with the challenges introduced by the autonomous units and the participation of humans, top-priority research directions and open questions are identified and detailed in the paper:

- Full-scale operational and maintenance transparency supported by the evaluation & assessment network;

- Active compensation of the safety defects induced by the security breaches;

- Data-driven and knowledge-based adaptive diagnosis;

- Resilient control and full life-cycle management;

- Ground-up compatibility with the security design;

- Other auxiliary key technologies.

In brief, the key research questions, the future research directions, and an outlook about the future vision of “Plant-Wide Process Monitoring” can be found in this roadmap paper.

This paper has been published in IEEE Open Journal of the Industrial Electronics Society

Check full paper at: https://ieeexplore.ieee.org/document/9300250