Remote-Timber: An Outlook for Teleoperated Forestry with First 5G Measurements

Authors: Aamir Mahmood, Sarder Fakhrul Abedin, Mattias O’Nils, Mats Bergman and Mikael Gidlund

Extended Abstract:

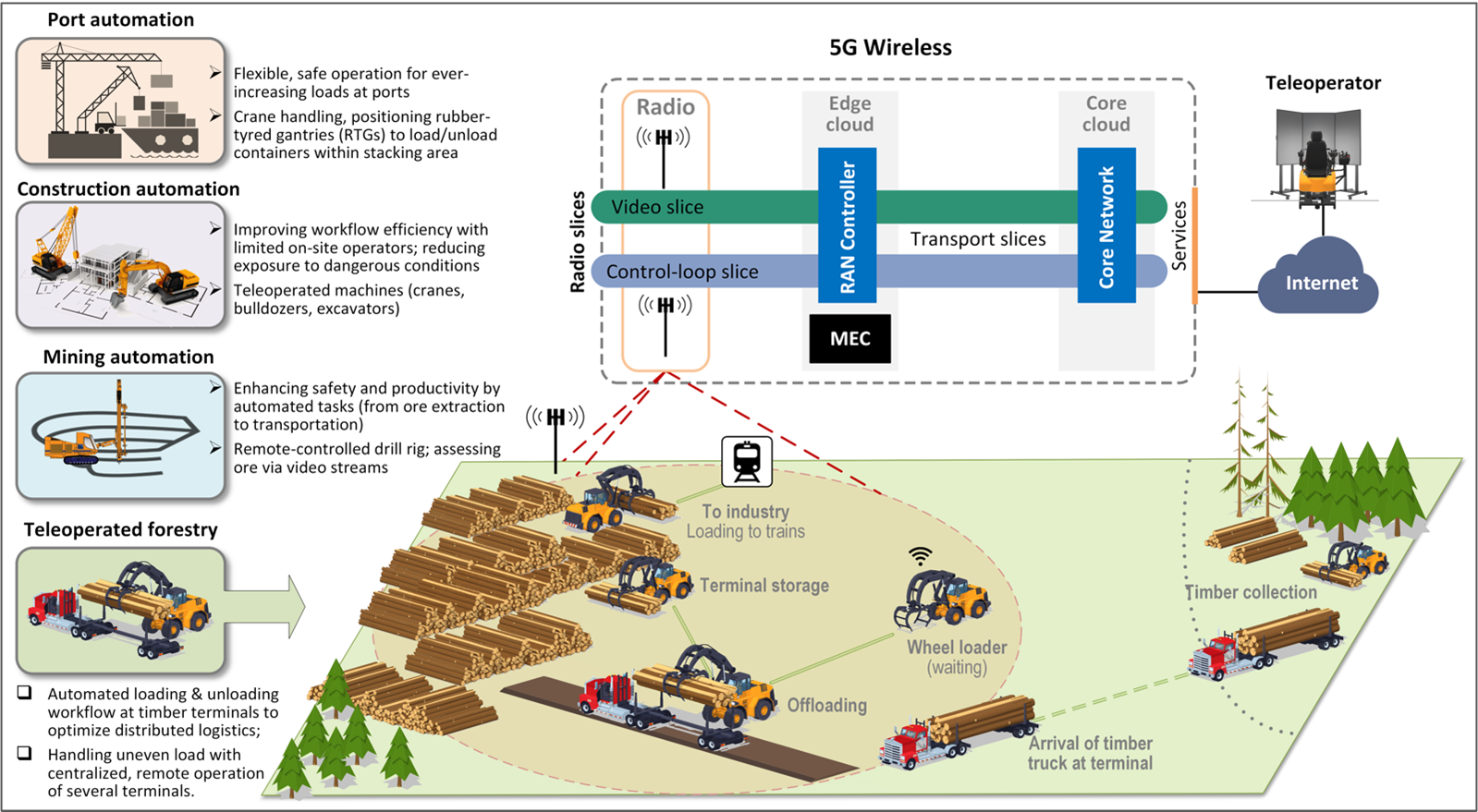

Across all industries, digitalization and automation are on the rise under the Industry 4.0 vision, and the forest industry is no exception. The forest industry depends on distributed flows of raw materials to the industry through various phases, wherein the typical workflow of timber loading and offloading is finding traction in using automation and 5G wireless networking technologies to enhance efficiency and reduce cost. This article presents one such ongoing effort in Sweden, Remote-Timber — demonstrating a 5G-connected teleoperation use-case within a workflow of timber terminal — and disseminates its business attractiveness, unique connectivity requirements/conditions, as well as first measurement results on network performance. The article also outlines the future needs of the 5G network design and optimization from the teleoperation perspective. Overall, the motivation of this article is to disseminate our early-stage findings and reflections to the industrial and academic communities for furthering the research and development activities in enhancing 5G networks for verticals.

Learn more about the current projects at Mid Sweden University closely linked to this article:

- Remote-Timer II: Robust wireless infrastructure for remotely controlled timber management (https://www.miun.se/en/Research/research-projects/ongoing-research-projects/robust-wireless-infrastructure-for-remotely-controlled-timber-management/)

- NIIT – Next Generation Industrial IoT (https://www.miun.se/en/Research/research-projects/ongoing-research-projects/niit—next-generation-industrial-iot2/)

- ENSURE-6G: Remote sensing and data fusion integration for Industrial logistics in rural areas with 6G (https://www.miun.se/en/Research/research-projects/ongoing-research-projects/ENSURE6G/)