Data Fusion System for Electric Motors Condition Monitoring: An Innovative Solution

Authors: Roque Alfredo Osornio-Rios, Israel Zamudio-Ramírez, Arturo Yosimar Jaen-Cuellar, Jose Antonino-Daviu, and Larisa Dunai

Extended Abstract:

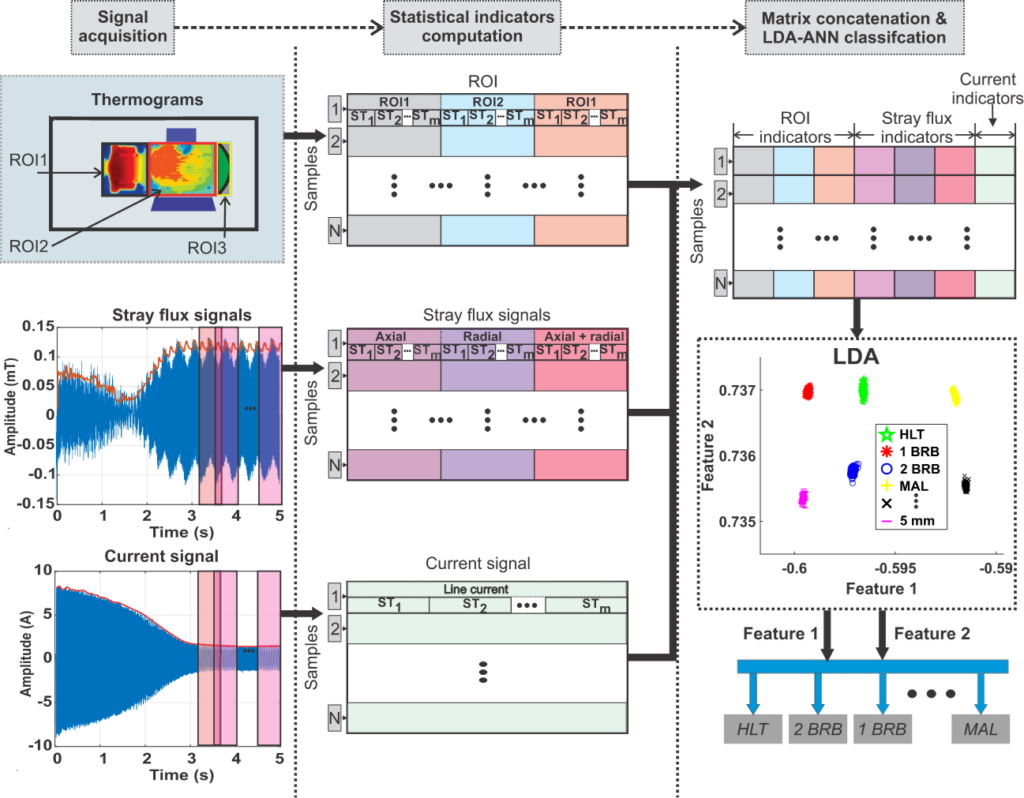

Electric motors are elementary drivers for various processes in countless applications concerning several areas of modern societies. This relevance can be mainly attributed to their high efficiency and robustness. However, due to their operating conditions, electric motors are subjected to different stresses that may lead to electromechanical damages, which, if not early detected, can cause irreversible failures and high repair costs as well as unplanned production downtimes. Moreover, damages in the different motor components reduce the motor efficiency since they increase the machine losses. In this regard, the analysis of different machine signals has aided in diagnosing these failures; however, few systems can merge the information from relevant signals to identify a wide range of faults under different operating conditions. Another aspect that is extremely relevant for the industry is that the signals used for diagnosis are intended to reduce the invasiveness over motors and machines. This allows the processes to continue their operation without production downtimes. This paper presents recent advances in the electric motor condition monitoring area, which have led to the development of a proprietary data fusion system (DFS) for automatic fault diagnosis. The DFS relies on the combined analysis of currents, stray magnetic fluxes, and infrared data, which can be measured in a non-invasive way by using simple and low-cost primary sensors. Regarding currents and stray-fluxes, the DFS integrates conventional techniques based on stationary analysis (e.g., MCSA) and a modern, robust methodology relying on the analysis of transient currents and fluxes by using advanced time-frequency transforms, which has proven to yield high reliability for the final diagnosis while requiring a low computational burden. With regards to infrared thermography, image processing techniques are developed. The system integrates a low-cost primary thermographic sensor as well as proprietary (ROI and statistics) tools for the analysis of the images. These diagnosis techniques are combined with the use of artificial intelligence methods for fault classification. The paper shows some results obtained when applying the system to the diagnose the condition of real electric motors, proving the capabilities of the developed methodology. The fusion of the three proposed quantities enables to complement to each other concerning the diagnosis of the considered faults, a fact that confers a high reliability to the final system.